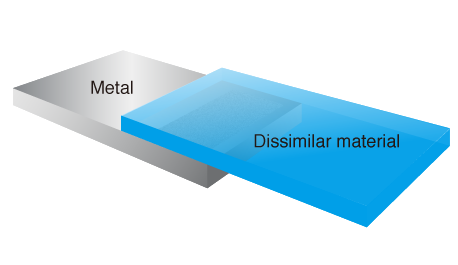

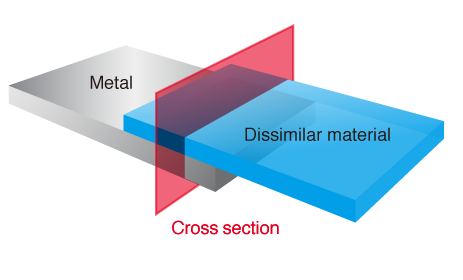

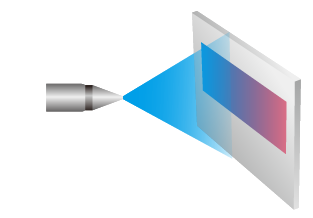

DLAMP is a revolutionarily joining technology for metal and dissimilar materials by use of laser.

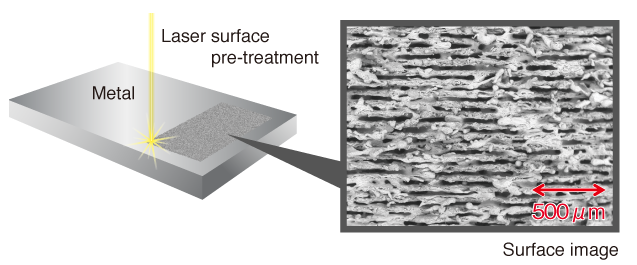

Secure joint with dissimilar material is achieved by creating anchor structure on the metal surface by laser treatment.

- Features

- 1. Applicable to various metal

- 2. No masking is required for partial treatment (Single-side treatment and patterning is possible)

- 3. Small environmental load (No chemical waste)

The Mechanism of DLAMP

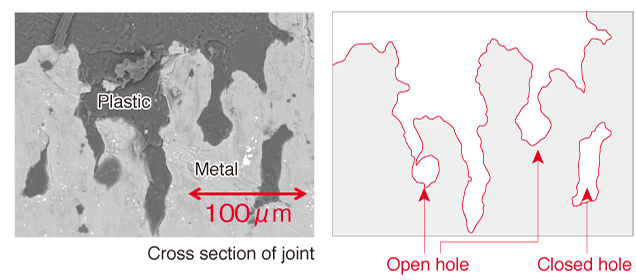

Anchor Effect :

The high joining strength is achieved by molten materials permeating through the voids (undercuts and tunnel-like structures) formed on the metal surface by DLAMP treatment.

Powered by kanazawa Institute of Technology

Masashi YAMABE –Masahiro SETO Laboratory.

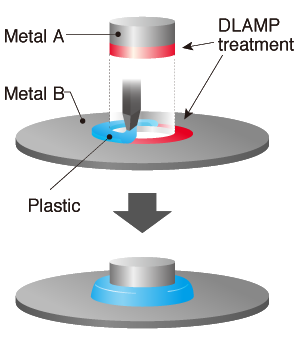

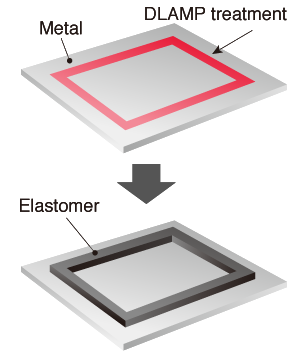

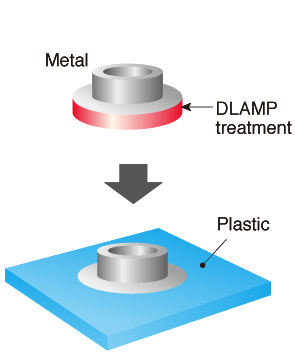

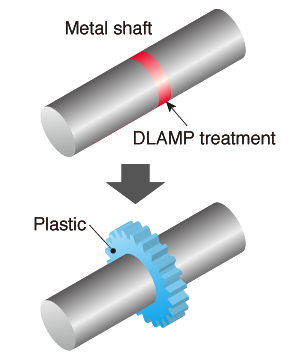

Composite molding

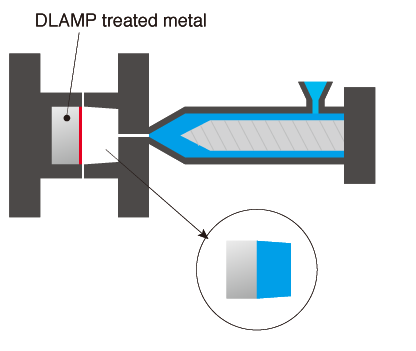

Injection molding

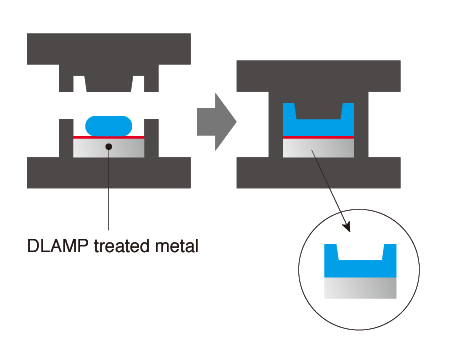

Compression molding

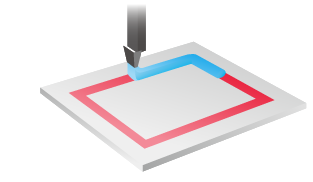

Dispencing

Spray coating / Thermal spraying

Examples of applications

Insulation / Sealing

Gasket

Metal Insert

Shaft

Applicable metal

| Metal | Experience | |

|---|---|---|

| Aluminum alloy | A2017 | |

| A5052 | ||

| A6061 | ||

| A7075 | ||

| ADC12 | ||

| Stainless alloy | SUS304 | |

| Iron alloy | SPCC | |

| SS400 | ||

| Metal | Experience | |

|---|---|---|

| Magnesium alloy | AZ31 | |

| AZ91D | ||

| Titanium alloy | Titanium(TP340) | |

| Titanium64(TAB6400) | ||

| Copper alloy | Copper(C1100) | |

| Brass(C2801) | ||

| Nickel silver(C7501) | ||

| Zinc alloy | ZDC2 | |

: Well experienced : Experienced

Coated metal

| Aluminum alloy | Alumite |

|---|---|

| Iron alloy | Chromate steel plate |

| Zinc plating | |

| Electrodeposition coating | |

| Copper alloy | Tinned copper |

Joint Strength

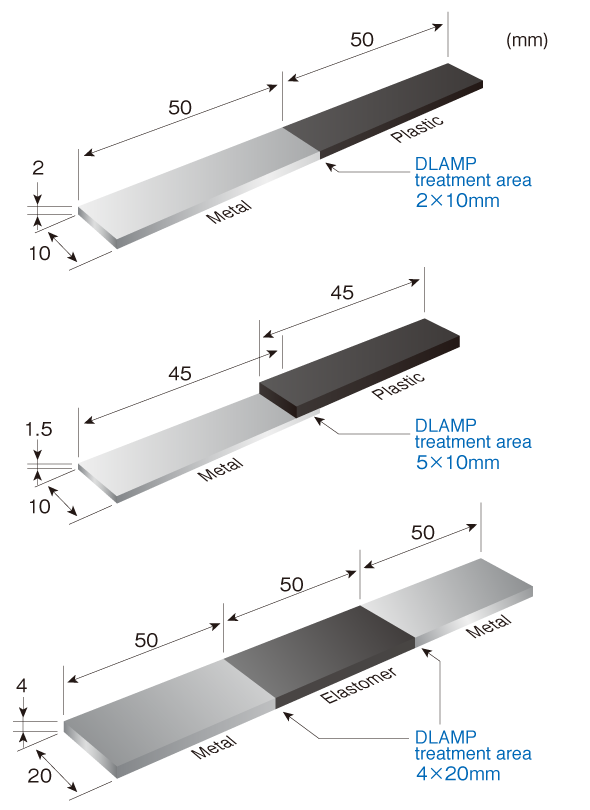

Thermoplastic

| Tensile strength (MPa) | Shear strength (MPa) | |

|---|---|---|

| PP/LGF40 | 25 | 20 |

| PBT/GF30 | 35 | 35 |

| PA66/GF30 | 50 | 50 |

| PPS/GF40 | 50 | 50 |

| PC/GF40 | 30 | 25 |

Metal : A5052

Test method : ISO 19095-3:2015

Elastomer

| Tensile strength (MPa) | Elongation at break (%) | |

|---|---|---|

| Silicone elastomer hardness 80 | 2.2 | 40 |

| Fluoroelastomer hardness 60 | 5.5 | 150 |

| Fluoroelastomer hardness 80 | 6.0 | 100 |

Metal : A5052 Test method : JIS K 6253

Technical Information

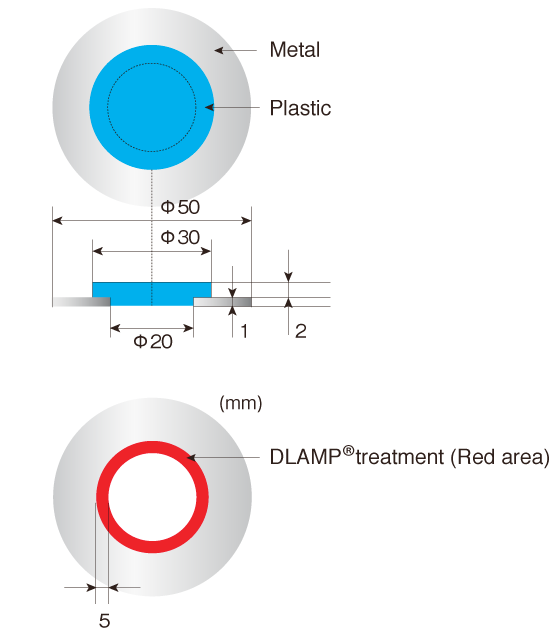

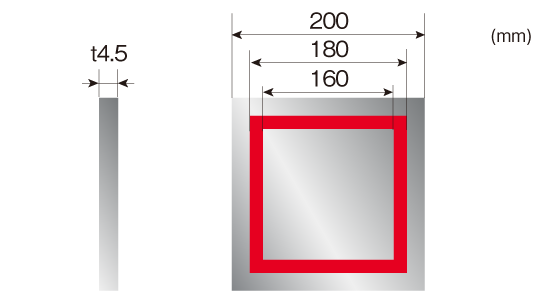

Airtightness data

(helium leak test)

Using DLAMP® treatment metal produce good airtightness.

- Plastics

- PPS/GF35%

- Test

- Helium leak

| Surface pre-treatment | Non-treatment | DLAMP®-treatment(width:5mm) | |||

|---|---|---|---|---|---|

| Metal | Aluminum alloy A5052 | Aluminum alloy A5052 | Stainless steel SUS304 | Brass C2801 | Magnesium alloy AZ91 |

| Helium leakage quantity |

|||||

| Helium leakage quantity (After heat cycle test) |

|||||

: A leakage quantity ≦ 5×10-7 Pa・m3/s

: A leakage quantity ≧ 5×10-5 Pa・m3/s

*Heat cycle test : -40°C (30 min) ⇔ 125°C (30 min), 500 cycles

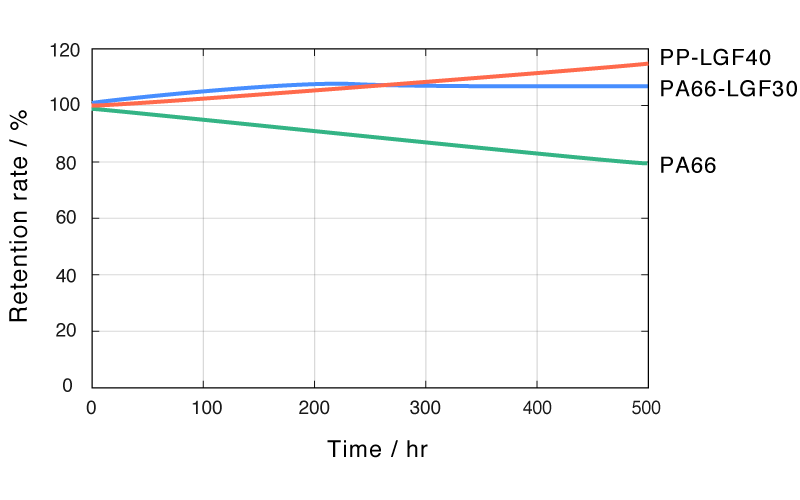

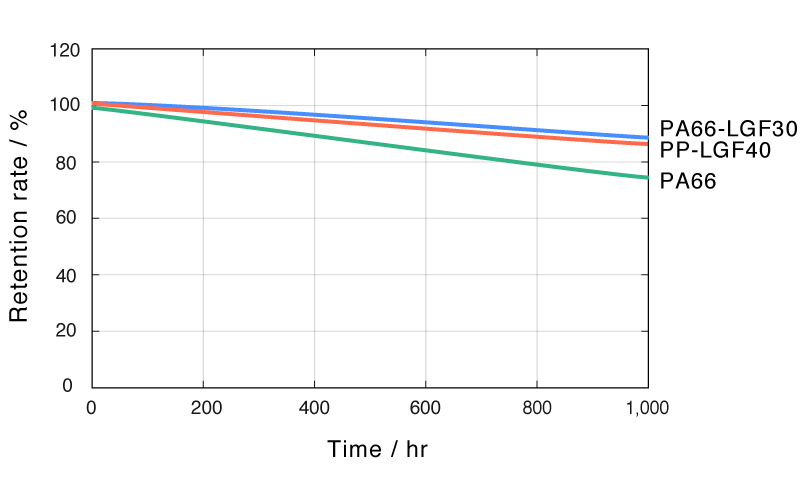

Joint durability

Heat Resistance test

- Test condition

- 120°C,500hr

- Test time

- 500hr

- Metal

- SUS304

- Plastics

- PP-LGF40

PA66-LGF30

PA66

Heat cycle test

- Test condition

- -40°C,1hr ⇔ 90°C,1hr

- Test time

- 1000hr

- Metal

- SUS304

- Plastics

- PP-LGF40

PA66-LGF30

PA66

DLAMP® treated samples

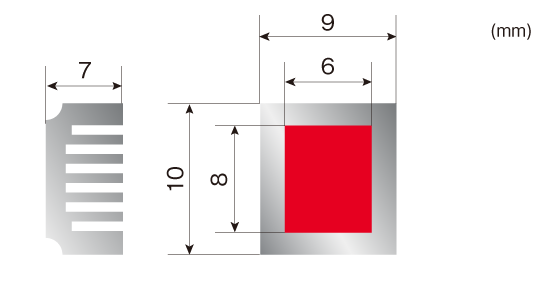

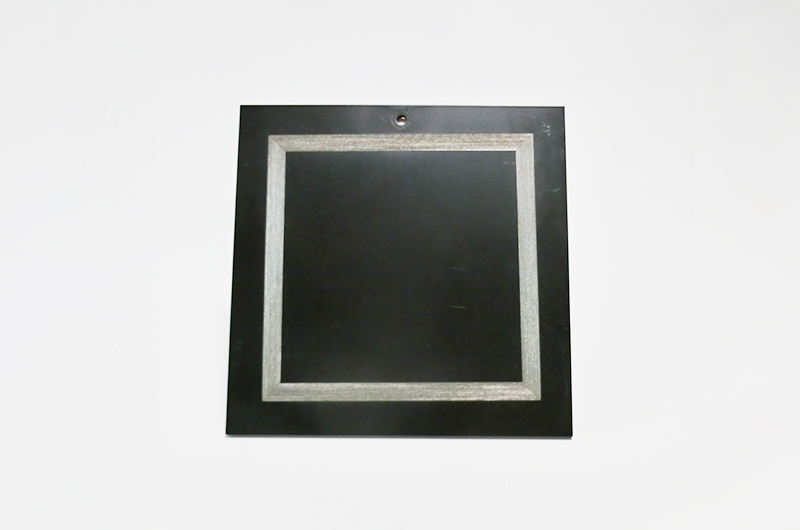

Anodized aluminum

- Form

-

| Metal | Anodized aluminum |

|---|

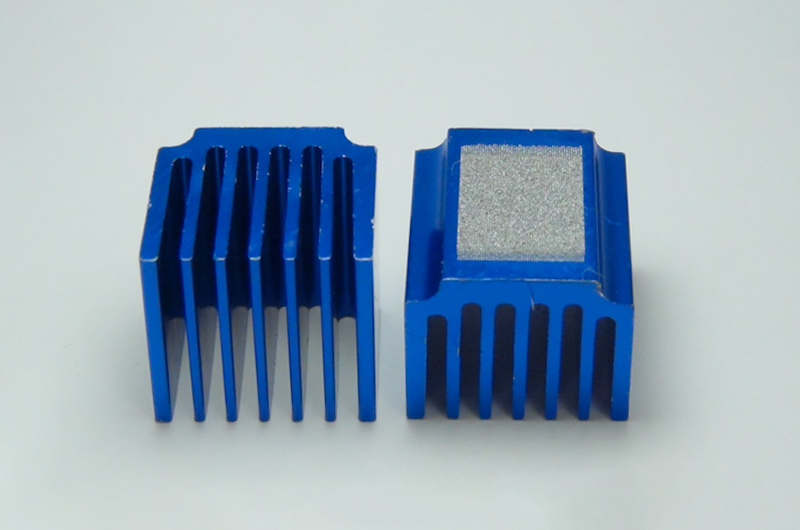

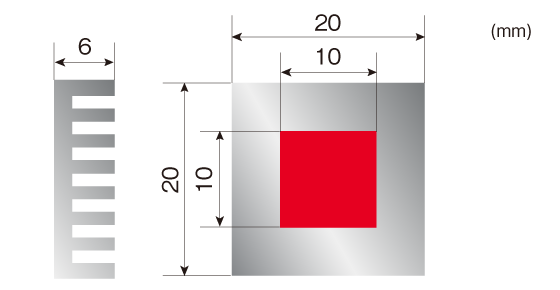

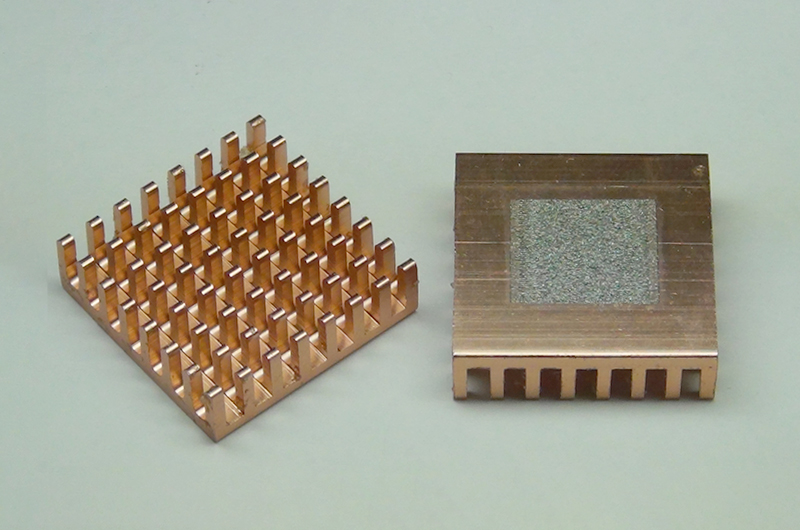

Heatsink

- Form

-

| Metal | Copper plating Aluminum |

|---|

Coated iron plate

- Form

-

| Metal | Electrodeposition coating iron |

|---|

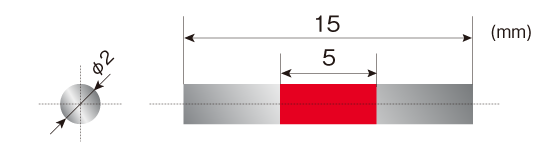

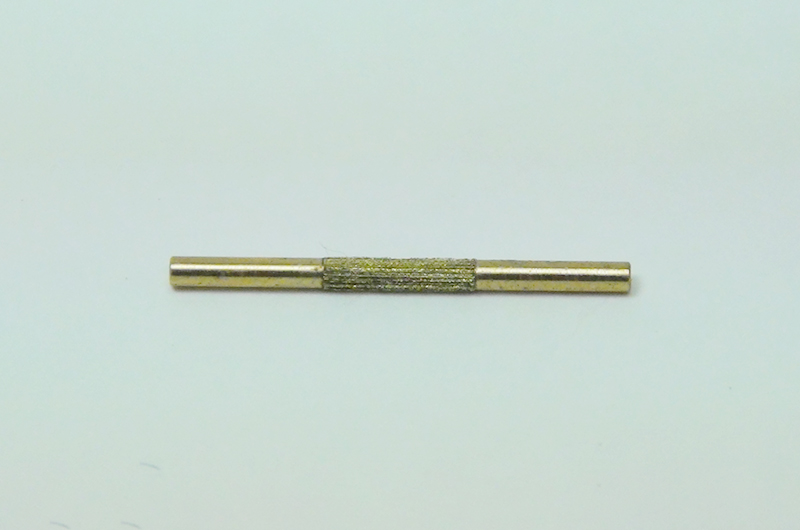

Brass pin

- Form

-

| Metal | Brass |

|---|

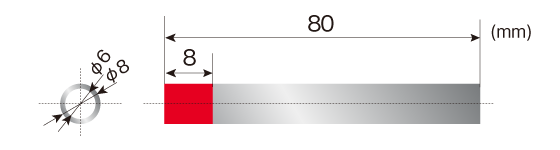

SUS Pipe

- Form

-

| Metal | SUS304 |

|---|

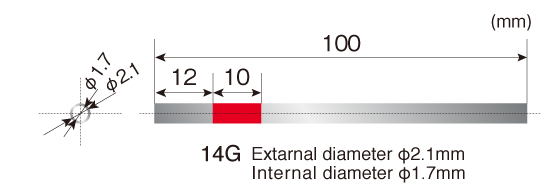

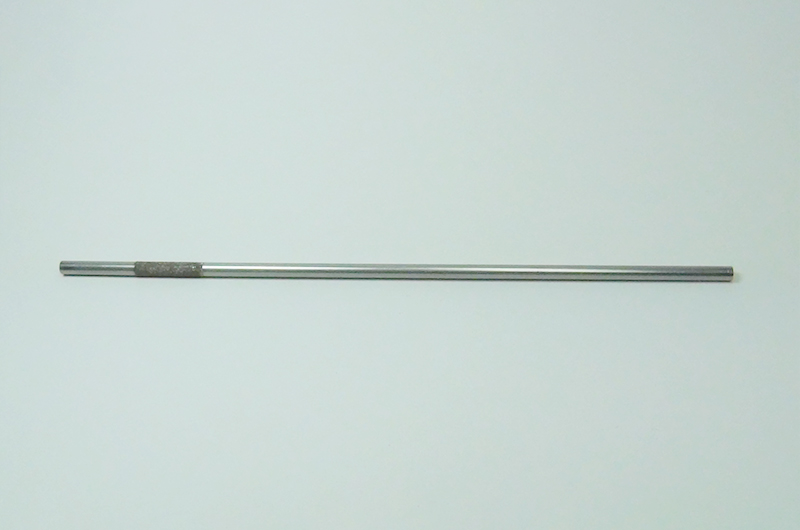

Tube

- Form

-

| Metal | SUS304 |

|---|

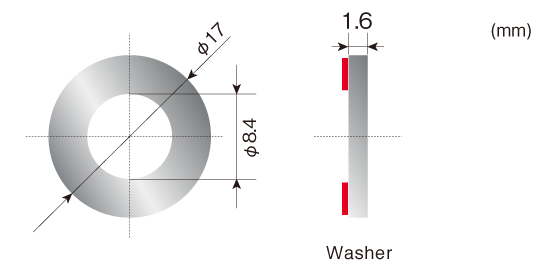

Washer

- Form

-

| Metal | SUS304 |

|---|

The information contained herein is all the data available at present.Unauthorized copying prohibited.

DLAMP® is a registered trademark of Daicel Miraizu Ltd.